In a world where urbanization continually changes how we transport goods, mini trucks have emerged as essential vehicles for local business owners, property managers, and enthusiasts alike. From their humble beginnings as Kei trucks in Japan to their modern adaptations, mini trucks blend compactness and efficiency. This article explores their evolution, design qualities that make them ideal for city driving, their economic impact on small businesses, and the technological advancements that are shaping the future of mini trucks. Whether you’re a small business owner looking to optimize deliveries, a residential property owner in need of reliable transport, or simply a mini truck fan, this guide provides valuable insights into understanding and appreciating these versatile vehicles.

Kei Trucks: The Global Mini Truck Revolution

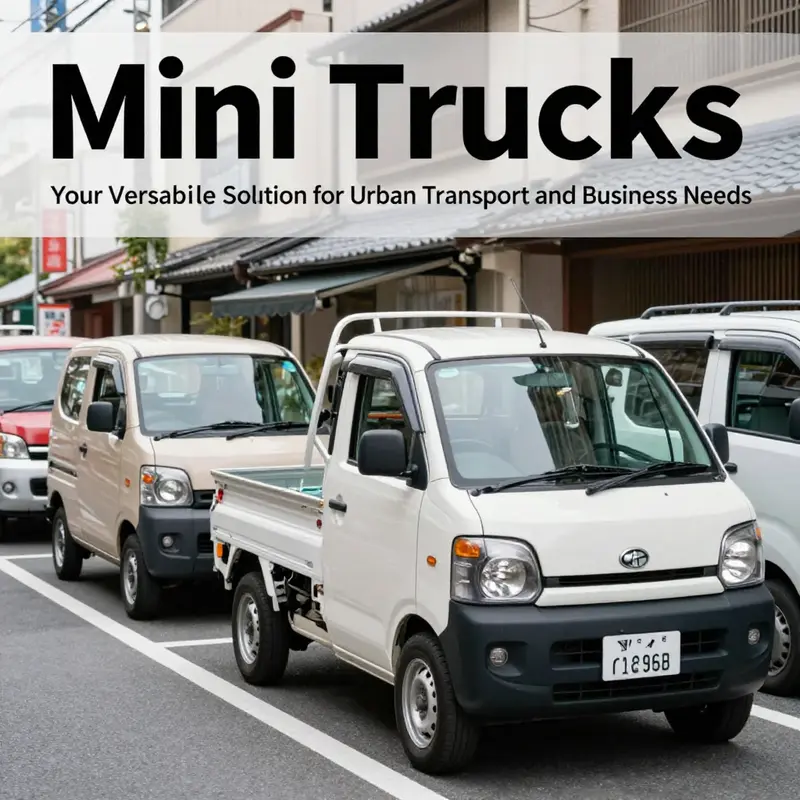

Across cities and farms, a small class of work vehicles quietly powers a wide range of daily tasks. Kei trucks, commonly defined by a 660 cubic centimeter engine limit and compact dimensions, offer a rare blend of maneuverability, efficiency, and affordability. They are not flashy showpieces; they are practical tools designed to shuttle goods through narrow streets, loading docks, and tight spaces where larger trucks struggle. Their compact footprint reduces fuel use, lowers insurance and licensing hurdles, and keeps operating costs predictable for small businesses, farms, and service fleets.

The origin story begins in Japan, where Kei-class regulations were crafted not as a curiosity but as a policy instrument. Engine displacement is capped at 660cc, dimensions are restricted, and tax and registration benefits reward compact design. The result is a vehicle that embodies efficiency by design: light weight, simple mechanicals, and a footprint that suits dense urban infrastructure. This regulatory ethos creates a platform that can be economical to own and easy to operate, enabling more participants in local logistics.

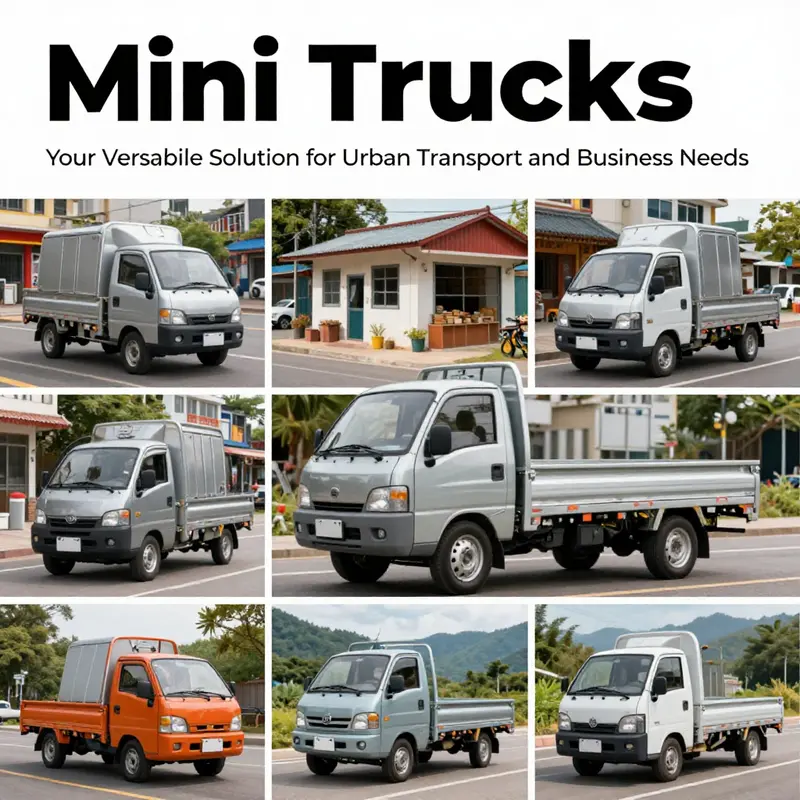

From the outset, Kei trucks were built to be versatile within their small scale. Design priorities center on maximizing usable volume within a narrow width, achieving surprising cargo space through tall body profiles and efficient chassis layouts. Configurations typically include closed vans, open cargo beds, and cab-chassis models that can be customized with aftermarket bodies for farming, maintenance, or service delivery. The essence is a vehicle that can traverse crowded streets and still be repurposed for different jobs without a major overhaul.

As Kei trucks gained traction, manufacturers explored export opportunities. Adapting for global markets meant preserving the core advantages—compact size, low operating costs, and reliability—while meeting diverse regulatory and safety standards. Some adjustments include left-hand drive configurations for markets on the opposite side of the road and the integration of modern safety systems. The result is a family of lightweight, economical trucks that remain true to the Kei philosophy while delivering value to fleets and individuals far from Japan.

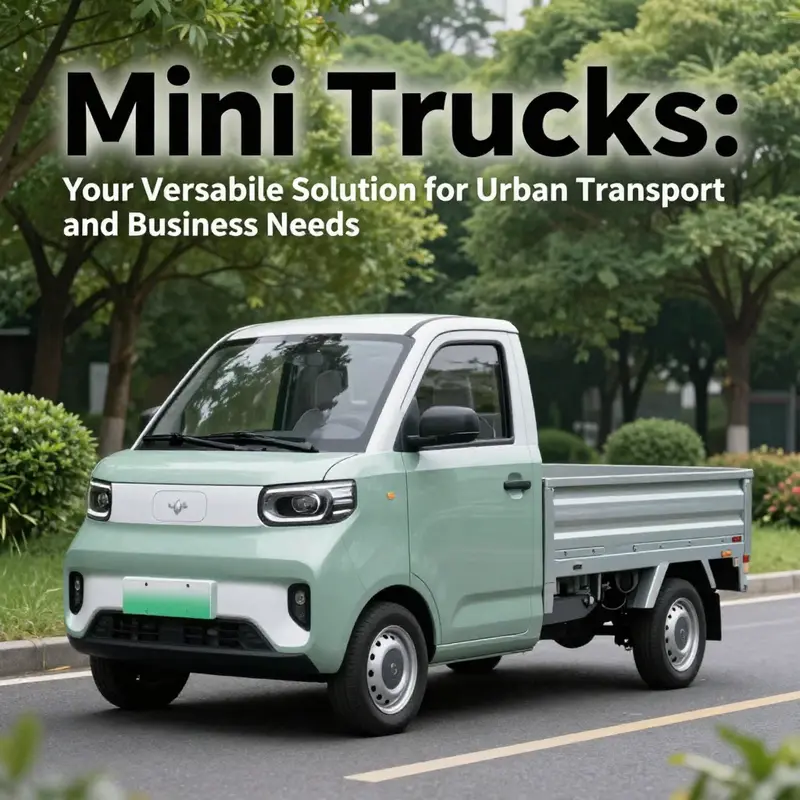

The modern era has brought electrification to the Kei story. Electric variants retain the small footprint and nimble handling while offering predictable maintenance costs and zero-tailpipe emissions. In urban logistics, these vehicles can slip through traffic, park easily, and operate with lower noise and emissions. The transition to electric power aligns with broader goals of cleaner fleets and quieter cities, while preserving the practical advantages that have defined Kei trucks for decades.

In practice, the business case remains compelling. The light weight and compact GVWR enable lower insurance costs and simpler licensing in many jurisdictions, while modular bodies allow for customization without expensive platform changes. For small operators facing rising labor costs and dense congestion, Kei trucks provide an efficient, adaptable solution for routine deliveries, fieldwork, and neighborhood services. The Kei approach demonstrates how targeted regulation can spur enduring innovation, producing a vehicle category that travels beyond its origins to serve diverse markets and needs.

Efficient by Design: How Mini Trucks Redefine Urban Freight and City Logistics

Cities are designed for efficiency, but freight is often a blunt instrument to move goods through crowded cores. Mini trucks emerge as a response to the stubborn friction of urban transport: narrow lanes, limited loading zones, and the daily pressure to deliver on time while keeping operating costs in check. They are not merely smaller versions of their heavier counterparts; they are purpose-built tools that optimize every stage of urban movement. At the heart of their appeal is a careful balance among size, weight, payload, and propulsion. The result is a vehicle that can slip into spaces larger vans struggle to reach, while still carrying significant loads and consuming far less energy per mile. For stakeholders who manage fleets of last-mile vehicles or run small businesses that rely on small-scale deliveries, mini trucks translate logistics into a practical, repeatable workflow rather than a sporadic series of compromises.

One of the most striking advantages of mini trucks is their compact footprint. In dense neighborhoods, every inch matters. Narrow streets and tight corners that would require careful planning for a traditional cargo van become routine obstacles for larger vehicles. The compact dimensions of mini trucks enable more direct routing and reduce the time spent circling for parking or waiting for loading docks. This capability is not just about speed; it translates into reliability. When a driver can access a delivery point without a long detour, the likelihood of missed time windows diminishes. In turn, that reliability bolsters customer satisfaction and enables better use of time across the day. The urban workday, with its frequent stops and dynamic stop-and-go traffic, rewards vehicles that can execute precise, predictable movements in constrained spaces. Mini trucks, with their nimble chassis and tight turning radii, often outperform larger counterparts in this specific context, turning city blocks into efficient delivery corridors rather than congested hurdles.

The lightweight construction that characterizes many modern mini trucks is another key driver of urban efficiency. Advances in materials science—such as the strategic use of aluminum alloys and high-strength steels—allow these vehicles to retain structural integrity while shedding substantial weight. Lighter weight yields several practical benefits. Reduced mass lowers fuel consumption and, in the case of electrified variants, extends range or reduces the size and cost of batteries needed to complete a typical urban route. Even when internal combustion engines power these machines, the incremental fuel savings accumulate quickly across a fleet that makes multiple daily trips. And when electric variants are involved, the advantage compounds with zero tailpipe emissions, which helps city air quality programs and aligns with increasingly stringent urban environmental standards. Zero-emission operation is not just about the absence of exhaust; it also signifies a quieter, smoother ride that minimizes vibration and improves driver comfort, a factor that matters when drivers make many short runs in a workday.

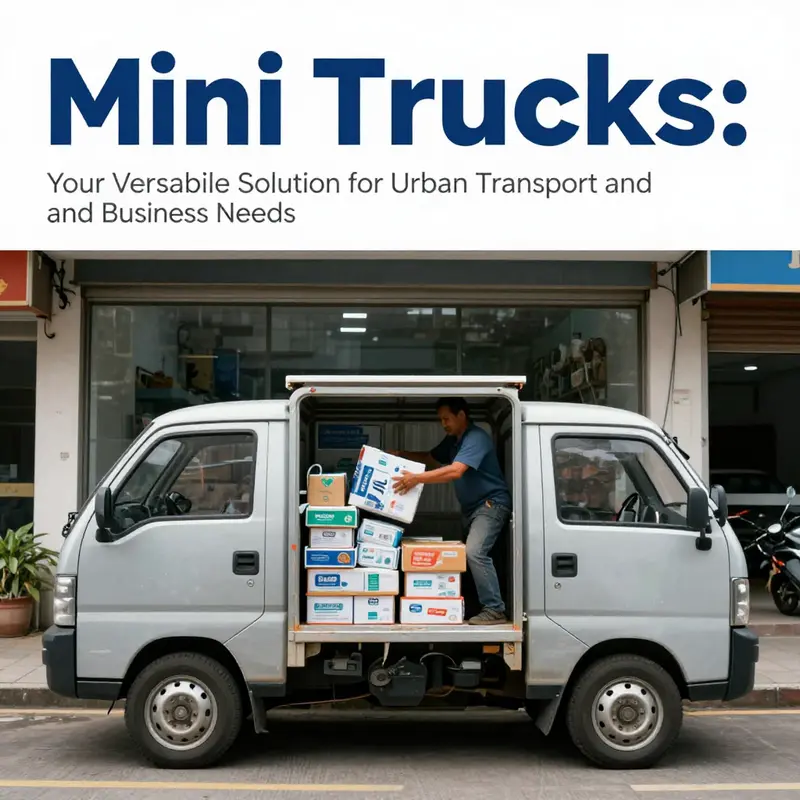

Cargo design is where the adaptability of mini trucks shines most clearly. The typical flatbed, box, or cab-chassis configuration is not a one-size-fits-all solution; it is a flexible platform that businesses can tailor to the exact nature of their work. For last-mile delivery, a compact cargo bed with modular tie-downs and accessible side panels enables quick loading and secure stowage of parcels, baskets, or small pallets. For mobile service tasks, a box or platform that can host a compact workshop, with power outlets and secure tool storage, becomes a moving workspace. This adaptability means that a single vehicle can be repurposed as business needs evolve—whether the daily task is vending, maintenance, or courier-style parcel distribution. The ability to reconfigure the cargo space without expensive retrofits reduces total cost of ownership and makes fleet planning more resilient to shifting demand patterns.

A distinctive element of mini trucks is their potential to be deployed in regional and municipal logistics strategies that emphasize last-mile efficiency. In many urban contexts, the last mile accounts for a disproportionate share of total transport cost, and it is precisely where maneuverability and right-sized capacity deliver the most value. The compact form factor makes micro-distribution feasible in neighborhoods that would be economically impractical for larger vehicles. It also opens doors to innovative service models, such as micro-warehousing close to high-demand districts, where compact fleets can stock high-turnover goods and execute rapid replenishment with minimal dwell time. These approaches are not theoretical; they reflect real-world practice where the right vehicle matches the street-scale reality of a given city. When a fleet that runs many small deliveries per day can execute more stops per hour and reduce idle time, the compounded effect is a meaningful uptick in overall throughput for the operation, even if each individual truck carries a modest payload.

The origin and spread of Kei-class, or Kei-type, vehicles offers further insight into why mini trucks feel so well suited to urban work. These vehicles were designed within regulatory frameworks that encourage small size and economical operation. The design philosophy behind Kei-class vehicles emphasizes efficiency in space use, engine displacement, and maintenance costs. While the regulatory landscape differs by country, the core idea remains consistent: maximize utility per liter of fuel and per kilogram of payload while staying compact enough to thrive in dense environments. This philosophy has helped spread the concept beyond its Japanese roots, informing how engineers approach optimization for urban fleets around the world. In practice, this means mini trucks are often tuned for short-range, high-frequency work—routes under a few dozen kilometers per day that require quick turnover, frequent stops, and dependable performance across varied urban surfaces.

In terms of propulsion, the transition toward electrification is a defining trend for urban logistics, and mini trucks are at the forefront of that shift. Electric variants respond directly to the demand for reduced emissions in city centers, where even modest improvements in air quality matter for residents and workers. Battery technology designed to support urban routes—short-range, predictable charging needs, and robust thermal management—makes these vehicles well-suited to daily duty cycles. For operators, the move to electric powertrains translates into lower operating costs over the vehicle’s life, with savings accruing from electricity costs that are typically lower than diesel or gasoline and from reduced maintenance needs associated with simpler drivetrains and fewer moving parts. The long-term financial logic of electric mini trucks aligns well with the economics of urban delivery, where energy efficiency and maintenance predictability can be nearly as important as upfront price.

Beyond powertrain and payload, safety and driver experience play a crucial role in delivering reliable urban performance. Lightweight construction does not imply fragility; modern mini trucks incorporate structural reinforcements and active safety features designed to protect occupants and pedestrians in dense traffic. The urban context rewards vehicles that offer crisp handling, stable braking, and clear visibility from the driver’s seat. A compact cab with good forward and side visibility helps drivers anticipate hazards, negotiate tight street corridors, and make precise placements at loading docks. The combination of agile handling and predictable braking behavior is a practical advantage when the street grid presents frequent cornering, close quarter maneuvers, and sudden pedestrians or cyclists weaving into traffic patterns. In practice, fleets that prioritize safety alongside efficiency tend to experience fewer incidents, reduced downtime, and less risk of costly damage to goods and infrastructure.

The narrative of mini trucks in urban transport is not a call to replace all larger vans or trucks, but a call to reallocate roles within a diversified fleet. For many businesses, a small, agile vehicle is ideal for the repetitive, time-sensitive tasks that dominate the middle of the day—near-dock deliveries, replenishment runs, service calls in dense neighborhoods, and quick outdoor loading tasks where space is scarce. Larger vehicles can still handle bulk freight, long-haul legs, or high-volume shifts, while mini trucks handle the fragmented, high-frequency tasks that define city logistics. This division of labor helps organizations optimize route planning, reduce congestion at major hubs, and maintain a steady tempo that keeps customer commitments intact.

As the urban landscape continues to evolve, the role of mini trucks will keep expanding in response to policy, market demand, and technology. City planners increasingly view micro-mupply chains as a way to increase resilience and reduce traffic impact by spreading activity more evenly across neighborhoods rather than concentrating it in centralized warehouses. In this context, mini trucks become not only a tool for moving goods but a strategic component of urban logistics design. The potential for integration with micro-fulfillment centers, dynamic routing algorithms, and real-time fleet analytics turns these small workhorses into intelligent nodes in a broader, data-driven system. The practical outcome is a logistics network that can adapt quickly to changing demand, weather, or traffic conditions while maintaining a dependable service standard for urban customers.

For practitioners seeking practical examples of how to leverage mini trucks in real-world settings, the available literature and case studies offer a wealth of insights. These sources emphasize how the right vehicle choice interacts with route planning, cargo configuration, and maintenance scheduling to produce measurable gains in efficiency and reliability. They also underscore the importance of aligning hardware with the actual work being done: the cargo space must be adaptable, the powertrain must match typical route lengths, and the vehicle must be easy to service within the constraints of urban infrastructure.

If you are exploring this topic for your operation, the broader conversation around mini trucks is not about novelty but about a pragmatic redesign of urban freight. It is about choosing a form factor that is inherently suited to the environment and the tasks at hand, then wiring that choice into a holistic fleet strategy. For readers who want to explore practical examples and owner perspectives, the Mini Truck Blog provides a curated view of how these vehicles are deployed in city settings and how operators adapt their fleets to evolving demands. Mini Truck Blog

Further considerations include the regulatory and environmental dimensions that influence adoption. Urban authorities increasingly reward lower-emission fleets, quiet operation, and reduced road wear. Mini trucks, especially electric variants, align well with such incentives, enabling fleets to qualify for incentives, exemptions, or favorable operating conditions in certain jurisdictions. The business case, then, rests not only on the mechanics of fuel savings or maintenance costs but also on a broader alignment with city policies that encourage sustainable logistics practices. This alignment helps explain why many fleets are transitioning a portion of their urban-facing duties to mini trucks even as they retain larger, higher-capacity vehicles for other parts of their operations.

In sum, the efficiency of mini trucks in urban transport arises from a deliberate synthesis of compact dimensions, lightweight yet sturdy construction, adaptable cargo configurations, and propulsion options that minimize cost and environmental impact. These characteristics translate into tangible advantages: faster delivery cycles, lower per-mile operating costs, better fit with crowded streets, and a level of versatility that enables businesses to tailor a fleet to the nuances of their specific urban footprint. The result is not just a vehicle but a strategic asset for urban logistics—one that can be deployed across a range of tasks with greater precision, predictability, and efficiency than traditional cargo vehicles. The chapter you have read links a practical, on-the-ground perspective with broader industry trends, inviting readers to imagine how a micro-scale approach to freight can ripple outward into more resilient and sustainable city logistics.

External reference for further reading on electric mini trucks and urban applicability: https://www.foton.com.cn/zh/product/electric-mini-truck/

Tiny Yet Tremendous: How Mini Trucks Reshape the Economics of Small-Scale Commerce

In the ledger of modern commerce, margins are earned in the margins—the narrow streets between storefronts, the alleyways that lead to loading docks, and the quiet hours when a fleet wakes the city without waking the neighborhood. It is in these spaces that mini trucks exert outsized influence. Defined by their compact size and a Gross Vehicle Weight Rating well under the threshold that marks full-sized workhorses, these vehicles blend lightness with sufficient cargo capability. They occupy a practical middle ground: not oversized enough to eat into fuel budgets or parking spaces, yet sturdy enough to move tools, parts, and produce with regular reliability. The underlying logic is simple and powerful. When a business moves goods within a city, every mile matters; every minute saved in maneuvering through tight streets translates into more deliveries completed, fewer delays, and a customer experience that feels seamless. The result is a chain of cost-conscious decisions that collectively alter the bottom line in a way that is immediately visible to a small enterprise, where liquidity and cash flow are as crucial as the goods themselves.

From the outset, miniature bodies bring a fundamental advantage: they sip rather than roar at the fuel pump. Compared with larger trucks, mini trucks are lighter, their engines smaller, and their aerodynamics optimized for short, recurring trips rather than long hauls. This isn’t mere arithmetic; it changes daily realities. A fleet that embraces these small, efficient work vehicles often reports noticeably reduced fuel bills month after month. Even if a single unit isn’t dramatically cheaper to own outright, the ongoing savings from lower fuel consumption compound quickly. For small businesses with tight margins, those recurring savings can free budget lines for hiring, inventory, or service improvements. Moreover, lower fuel needs correlate with a smaller carbon footprint, which has become an increasingly important criterion for clients and partners who want to collaborate with operators that align with environmental sustainability goals. In many communities, this alignment is not simply a philosophical preference but a practical business decision that supports green branding, compliance with municipal programs, and favorable considerations in local procurement processes. While fuel economy is a central driver, it is only one side of a broader economic argument.

Beyond fuel, the financial flexibility attached to mini trucks is a quiet but powerful engine of business agility. For small operators, the option to rent rather than own provides a lifeline that scales with demand. Seasonal peaks, one-off projects, or sudden shifts in client demand can strain a business plan built on a fixed asset base. In such moments, renting a compact cargo vehicle becomes a strategic lever, allowing a company to expand capacity without committing capital. This flexibility also supports more nuanced asset management strategies. Rather than tying up capital in a single multipurpose vehicle, a business can diversify its transport mix—drawing on different vehicle configurations to match specific jobs. A closed cargo van for sensitive or high-value deliveries, an open-bed mini truck for quick-load tasks, or a cab-chassis setup ready for a specialized body—these options let a small operation tailor its fleet to the work at hand while keeping total ownership costs in check. The effect on cash flow is often transformative: short-term expenses stay predictable, while long-term liabilities are kept at arm’s length, enabling more precise budgeting and less exposure to debt service pressure during lean periods.

The true value of mini trucks, however, reveals itself in the space where urban logistics meet real-world constraints. A compact footprint matters because it translates to time saved negotiating dense traffic, squeezing into tight loading zones, and parking in spaces that a full-size truck would simply bypass. In cities and towns where curb space is at a premium, the ability to turn, maneuver, and park with ease becomes a line item on the efficiency calculator. The payoff is not only speed but reliability. Deliveries arrive on schedule because drivers spend less time circling blocks or negotiating missed turns. The improved predictability strengthens customer relationships, too. When clients know a delivery window will be met consistently, their own planning improves, and through the indirect network of repeat business and referrals, a small operation gains a moat of customer loyalty that is hard to replicate with larger, less nimble fleets. These advantages accumulate, creating a virtuous cycle: faster deliveries reinforce trust, which in turn yields better reviews, more referrals, and the capacity to take on additional local clients without expanding the fleet without careful consideration of ongoing costs.

In addition to the everyday economics of urban transport, many mini trucks offer configurations that broaden a business’s practical reach. The models range from open cargo beds that simplify loading of bulky items to enclosed cargo vans that protect sensitive inventory from weather and theft. There are cab-chassis layouts designed to accommodate specialized bodies, enabling a company to add a flatbed, a dump bed, or a tailored utility unit as project demands evolve. This versatility translates into a single fleet allowing a business to tackle a wide spectrum of tasks—from quick pickups on a construction site to transporting tools between jobsites and markets. The ability to swap or add different body types without stepping up to a different vehicle size reduces not only downtime but also the learning curve for operators who already handle multiple tasks in one workday. A driver accustomed to a compact, agile vehicle can adjust to a new body configuration with minimal training, which strengthens workforce efficiency and reduces the potential for errors during critical operations.

For many operations, off-road capabilities matter, too. A subset of mini trucks is designed to handle unpaved or uneven terrain, with features like higher ground clearance and four-wheel-drive traction. In rural settings or on job sites where paved roads give way to gravel or dirt, these variants maintain access to locations that would otherwise be off-limits or require a more expensive, larger vehicle. The practical outcome is reduced downtime. When a project’s logistics depend on reaching a remote site to retrieve materials, transport equipment, or stage debris for removal, the ability to reach those points without diverting into secondary transport channels preserves time and labor. It also lowers the risk of schedule slippage, which can cascade into missed deadlines and penalty clauses in contracts. Of course, the trade-offs exist—these capable variants may consume more fuel on rough terrain and require more maintenance than their urban-focused kin. Yet for businesses that routinely operate in challenging environments, the payoff in reliability and site access can be decisive, turning what could be a costly logistical obstacle into a routine, linear workflow.

Equally important is the productivity uplift offered by specific functional enhancements that some mini trucks provide. For many crews, tools and materials are bulky but light enough for a smaller vehicle when managed efficiently. A hydraulically operated tilting bed, for example, can dramatically reduce the manual labor required to unload materials, streamline dumping tasks, and accelerate job-site throughput. On construction sites, farms, or service operations, this capability translates into more trips completed per shift and less physical strain on workers. The cumulative effect is not merely time saved; it is a smoother labor lifecycle, with fewer injuries and less fatigue that can erode efficiency over time. A manager observing this effect will notice a direct correlation between equipment capability and workforce productivity, a relationship that matteringly reinforces the business case for a carefully chosen mini truck fleet.

In parallel with evolving configurations and payload capabilities, the growing availability of electric variants brings a new dimension to the economic argument. Lithium-ion battery power promises zero-emission operation within a city’s low-emission zones, a feature that is increasingly valued by municipalities and customers who prize sustainable transport. Electric mini trucks can significantly reduce maintenance costs over the long run since they have fewer moving parts and no internal combustion engine to service. The consequence is lower downtime for repairs and, crucially, fewer routine maintenance cycles that can divert technicians away from billable work. The financial implications extend beyond fuel savings to encompass total cost of ownership. While the upfront price premium for electric models can be higher, the ongoing savings from electricity, reduced maintenance, and potential government incentives can narrow the gap over a vehicle’s lifecycle. For small businesses with tight liquidity, the option to run a quiet, clean, and dependable work vehicle in dense urban spaces adds a qualitative advantage as well: it signals reliability and modernity, which can be leveraged in client communications and branding efforts without heavy investment in marketing spend.

From a broader perspective, the economic impact of mini trucks on small businesses is not only about the cost lines that appear on monthly statements. It is also about how these vehicles enable access to markets that were previously less reachable for smaller operators. A compact, fuel-efficient, adaptable fleet expands the reach of intra-city logistics, enabling delivery to more customers and presenting opportunities to explore same-day or next-day service levels that were not viable at scale with larger trucks. This expansion is not merely about increasing volume; it is about expanding service versatility. A small business can extend its geographic footprint for curbside pickups, home repairs, or last-mile logistics without committing to a costly shift in fleet size or a wholesale switch to more expensive transportation options. In many communities, that accessibility is a differentiator—the difference between winning a valued contract and watching a competitor seal the deal because the buyer needed a more flexible, responsive delivery partner.

The evidence of these economic dynamics is reinforced by field analyses and industry studies that emphasize how mini trucks function as strategic assets for small enterprises. They are not simply lower-cost transportation devices; they are versatile, practical platforms that support a broader set of business processes. The integration of a compact vehicle into a larger workflow—ranging from inventory management and route optimization to on-site logistics and customer service—creates a holistic improvement in efficiency. When a business can shrink the time between order and delivery while maintaining or improving reliability, the customer value proposition strengthens, and the business gains a competitive edge in tight markets. The story is not about a single advantage but about the synergy among savings, flexibility, and productivity, a synergy that compounds over time as the fleet evolves and business scales.

For readers seeking more real-world context and practical considerations, industry discussions and case studies capture the nuances of deployment. A respected resource in this space aggregates operator experiences, offering insights into how small firms tailor their transport assets to fit distinct operational needs. The conversations documented there emphasize not only economic gains but also the importance of planning around maintenance, safety, driver training, and regulatory compliance. To connect readers with that broader dialogue and to offer a starting point for those considering a pilot program or a staged fleet expansion, a quick reference can be found in the Mini Trucks Blog, which provides ongoing reflections from operators who are navigating the realities of urban logistics and light freight. For those who want to explore practical implications and trends, follow this link: Mini Trucks Blog.

In closing, the macroeconomic takeaway is undeniable: mini trucks, by virtue of their balance of payload, efficiency, and adaptability, reshape how small businesses think about transport. They enable more agile operations, support flexible capital strategies, and help companies deliver on service promises in ways that scale in a city’s most demanding corridors. The economic model they support hinges on continuous optimization—selecting the right mix of configurations for the job, coordinating with drivers and schedules to minimize empty trips, and staying attentive to evolving technologies such as electrification that promise further reductions in operating costs. As markets evolve and urban logistics become ever more critical to consumer expectations, mini trucks will likely grow from a niche tool to a standard component of small-business fleets, not as a flashy trend but as a durable and practical solution to the perennial challenges of cost control, service reliability, and market expansion. Their impact is felt not only in the numbers on an annual balance sheet but in the daily rhythm of service delivery, the reliability of customer experiences, and the resilience of small enterprises when competing in a crowded, dynamic urban economy. External resources and industry insights continue to illuminate how this segment evolves, guiding operators toward smarter purchases, better maintenance planning, and more strategic fleet management that aligns with the broader arc of sustainable and efficient local commerce. External resource: https://www.reuters.com/business/autos-transportation/economic-impact-mini-trucks-small-businesses-2026-01-20/

Electric Lanes and Smart Payloads: How Mini Trucks Are Redefining Urban Logistics

Mini trucks occupy a unique niche in the spectrum of commercial mobility. They are not just smaller versions of full-size delivery vans or pickup trucks; they are purpose-built for a balance between load capacity, maneuverability, and fuel efficiency. Their design philosophy centers on efficient cargo transport within dense urban contexts, narrow byways, and construction sites where larger vehicles struggle to maneuver. A typical mini truck maintains a gross vehicle weight rating (GVWR) under 8,500 pounds, a threshold that signals both regulatory considerations and practical economics. The emphasis is not simply on carlike economy but on a workhorse mentality: a platform that can shuttle goods, tools, and materials with predictable reliability in environments where time, space, and energy matter in equal measure. In this sense, mini trucks have evolved from niche curiosities into essential instruments for modern logistics and small-business operations, capable of bridging the gap between micro-mobility and traditional commercial transportation.

The configurations of mini trucks illuminate their flexible purpose. They arrive as closed cargo vans that protect contents from weather and theft, open cargo beds that maximize accessibility and simplify loading, and cab-chassis models that can be adapted for specialized attachments. This versatility matters because the day-to-day needs of users—whether a market stall operator, a building contractor, or a municipal maintenance crew—vary widely in the type and size of payload. The Kei truck, a subset steeped in Japan’s regulatory framework, has long served as a model of efficient design. Kei trucks are celebrated for their exceptional fuel economy, low maintenance costs, and their ability to thread through crowded streets and tight alleys. While their fame began near the island nation that shaped their regulatory environment, the Kei approach has broad resonance as urban logistics increasingly values compact footprints paired with sustained productivity.

In the current era, the shift from traditional internal combustion engines (ICE) to electric propulsion is reshaping expectations around mini trucks. The move toward lithium-ion battery power promises zero-emission operation and lower long-term maintenance footprints. Yet the electric transition does more than reduce tailpipe emissions; it recalibrates the economics of operation. A vehicle that costs less to fuel and service over its lifetime translates into more predictable total-cost-of-ownership for fleets that must rack up miles in urban routes, on construction sites, or through municipal service programs. The electrification trend extends beyond the powertrain: it intersects with lightweight materials, advanced drivetrains, and smarter onboard systems that together push mini trucks from simple transport platforms into adaptable, data-rich work aids.

Technological integration is advancing at a pace that makes old assumptions about small commercial vehicles seem quaint. Modern mini trucks increasingly weave automation, Internet of Things (IoT) connectivity, and sophisticated lightweight materials into their cores. These elements work in concert to improve efficiency, safety, and operational performance. Automation—ranging from guided parking assists in tight spaces to potential semi-autonomous functions on selected tasks—complements the human operator rather than replacing it. IoT connectivity enables real-time monitoring of battery health, brake wear, tire condition, route adherence, and cargo security. Weight-reducing materials and clever chassis engineering keep payload capacity respectable without inflating energy consumption. The net effect is a platform that collects and communicates data, supporting a broader ecosystem of fleet management and predictive maintenance.

Even within the broader family of mini trucks, the sector is seeing a notable specialization in the tipper segment. Tippers add dynamic capability—often in construction, municipal services, and waste management—where tipping action turns a compact vehicle into a mobile debris or material handler. In this domain, AI and telematics enter as force multipliers. Real-time condition monitoring identifies unexpected wear or failing hydraulics, while telematics optimize route planning, fuel use, and service intervals. The interplay between AI-powered diagnostics and remote connectivity reduces downtime and improves safety, particularly when crews maneuver in constrained sites or operate in harsh weather. The same digital lens that guides a delivery route now guides how a tiny truck manages a heavy load and communicates its status to a central operations hub.

These shifts are not merely about gadgets or gadgetry. They reflect a broader rethinking of what a small, purpose-built vehicle can do within a modern logistics stack. Regulators around the world are pushing for cleaner transportation solutions, and the mini truck segment has responded by embracing electrification, not as a trend but as a practical response to policy and market demand. Battery technology continues to evolve, expanding the feasible range for urban routes and enabling charging infrastructure to become a more integral part of day-to-day operations. As battery density improves and charging networks mature, electric mini trucks gain viability for longer routes and more demanding use cases that once seemed exclusive to larger, more expensive platforms. This progress underpins a fundamental shift in the transportation landscape: the move from fossil-fuel dependence to smart, clean, and connected mobility solutions that can scale down to lightweight, nimble platforms without sacrificing reliability or payload capacity.

The electrified and connected future of mini trucks does not occur in a vacuum. It sits at the intersection of material science, power electronics, and data analytics, all of which contribute to a more sustainable and resilient form of urban logistics. Batteries, motors, and drivetrains are continually refined to deliver higher energy density, faster charging, and longer life. Lightweight materials—advanced polymers, high-strength steels, and composite components—reduce frame mass, which translates into better efficiency and payload reserves. These engineering choices ripple through daily operations: a lighter truck uses less energy to move the same load; a more energy-dense battery extends the actuation window before a recharge is needed; smarter materials and more precise control systems translate into smoother handling and safer operation in crowded cities.

A central narrative of this progression is how data transforms practice. Real-time telemetry and fleet analytics move the needle from reactive maintenance to predictive care. A small maintenance issue detected early by onboard sensors can avert a breakdown in the middle of a dense urban corridor. Predictive maintenance reduces unexpected downtime, lowers repair costs, and extends the usable life of the vehicle. This data-driven approach also informs procurement and deployment strategies. Fleet managers can balance a portfolio of ICE and electric mini trucks, tailor charging schedules to lower electricity costs, and optimize asset utilization. In other words, smart data practices enable mini trucks to function not merely as isolated transport units but as integrated nodes in an intelligent logistics network.

The broader context for these transformations includes the adoption of electric drivetrains in related segments, such as electric drive mining trucks. While mining operations may look distant from city streets, the underlying technical lessons—thermal management, battery safety, ruggedized electronics, and reliability under demanding duty cycles—translate across applications. The gains in energy efficiency, reduced fuel consumption, quieter operation, and lower maintenance demands are attractive to any operation that values predictable costs and reduced environmental impact. The cross-pollination of technologies across domains accelerates the pace at which mini trucks become more capable, safer, and more economical to run. In this light, the mini truck is not a temporary phase in vehicle design but a persistent evolution toward more adaptable, data-forward, and environmentally responsible mobility.

From a design and user experience perspective, the modern mini truck must strike a balance between utility and ergonomics. The cab layout, visibility, noise levels, and control intuitiveness all affect operator fatigue on long days of work. A compact footprint enhances maneuverability, but it must not come at the expense of driver comfort or payload safety. Advanced driver-assistance systems, including rear cross-traffic alerts, hill-start assistance, and stable braking in varying weather, contribute to safer operation in pedestrian-rich urban environments. In the electric variant, regenerative braking can shorten stop distances and improve efficiency, while quiet operation reduces fatigue and increases the sense of control for the driver in congested streets. These human-centered improvements complement the machine-centered advances in powertrains and connectivity, weaving together a user experience that makes the mini truck a credible, repeatable choice for a wide range of tasks.

The internal conversation around these vehicles increasingly includes a simple, practical idea: efficiency is not just about how much you can carry, but how reliably you can move it, under what conditions, and at what cost. The compact footprint of mini trucks enables access to spaces that larger vehicles cannot reach, from crowded urban alleys to the tail ends of construction sites. Their lighter weight and efficient powertrains mean fewer emissions per mile and lower operating expenses, which matters as sustainability becomes a more salient factor in procurement and policy. When a fleet considers electrified vehicles, the conversation shifts from “upfront price” to “total cost of ownership,” including electricity costs, maintenance, downtime, and residual value. In this framing, mini trucks are not just smaller transport units; they are strategic assets that can bend urban logistics toward more predictable schedules, lower emissions, and smarter use of space.

To appreciate the practical implications for users on the ground, it helps to connect the design and technology narrative to real-world usage. A small business that delivers fresh produce to supermarkets and street markets may benefit from a closed cargo variant that keeps contents secure while offering easy access for unloading into bustling stores. A tradesperson who carries tools and materials might rely on a cab-chassis model that can be customized with racks or enclosures to fit a particular workflow. Municipal crews performing street maintenance or park services might prefer a tipper variant that can move loose material with minimal effort and downtime. Across these contexts, the underlying thread remains constant: the modern mini truck is a platform designed to multiply the impact of human labor through intelligent engineering, electrification, and digital integration. The result is a vehicle that can navigate tight spaces, deliver reliable service on a tight budget, and participate in a broader network of data-driven operations.

For readers seeking a practical entry point into model comparisons and specifications without losing sight of the broader arc, a consolidated reference can be helpful. A dedicated resource that aggregates practical comparisons can illuminate how small fleets choose between configurations, payload options, and powertrains. This kind of resource helps translate the theoretical advantages of electric mini trucks into concrete planning decisions for a specific business or municipal objective. (Mini Truck Blog) provides accessible perspectives on how enthusiasts and operators discuss and evaluate these vehicles in daily life, including how real-world use cases map onto the capabilities described above. While the world of mini trucks is diverse, the throughline remains clear: the best choices are those that align with the rhythm of the user’s work, the constraints of the operating environment, and the trajectory of sustainable, connected mobility.

Externally, the market context for these vehicles continues to mature as consumer and regulatory expectations push for efficiency, safety, and reliability in urban logistics. The ongoing development of charging infrastructure, improvements in battery technology, and advances in lightweight materials collectively expand the envelope of what is practical for a small, nimble vehicle to accomplish. As the ecosystem around mini trucks grows—spanning fleets, maintenance networks, and software platforms—their role in daily commerce and service delivery becomes more pronounced. The combination of compact form, adaptable configurations, and an integrated digital tail allows these vehicles to perform with a level of reliability that competitors must respect. In this sense, mini trucks are not a diminishing niche but a robust response to the contemporary demands of urban living and commercial activity.

For readers who want a more expansive picture of how the mini truck landscape is evolving, the literature and market analyses emphasize a common point: electrification is not a peripheral upgrade but a central driver of capability, cost efficiency, and environmental stewardship. The convergence of battery advancement, smarter vehicle electronics, and data-driven fleet management is redefining what “compact” can mean in a modern transportation fleet. As cities worldwide grapple with congestion, air quality concerns, and the need for resilient logistics networks, mini trucks offer a compelling combination of small-footprint practicality and large-footprint performance in terms of uptime, payload flexibility, and long-term value. They embody a pragmatic response to constraints that once constrained only larger, more expensive vehicles, proving that compact engineering and thoughtful software can deliver a level of capability that meets and sometimes exceeds the demands of contemporary work.

Internal link for further context on model configurations and specifications can be found here: Mini Truck Blog.

External resource for market-level insights: https://www.marketsandmarkets.com/Market-Reports/minitrucks-market-145891775.html

Final thoughts

As we have seen throughout this exploration, mini trucks are not just vehicles; they are solutions tailored for the modern urban landscape. From their origins in Japan as Kei trucks to their modern electric variants, mini trucks offer versatility, efficiency, and economic advantages for small businesses and residential needs. Their design prioritizes accessibility and maneuverability, making them ideal for navigating congested urban areas. With ongoing technological advancements, these compact vehicles are poised to become even more integral as we move toward sustainable solutions. Whether you are a business owner aiming to improve your delivery efficiency or an enthusiast eager to join a vibrant community, embracing mini trucks can lead to numerous benefits, both practical and enjoyable.