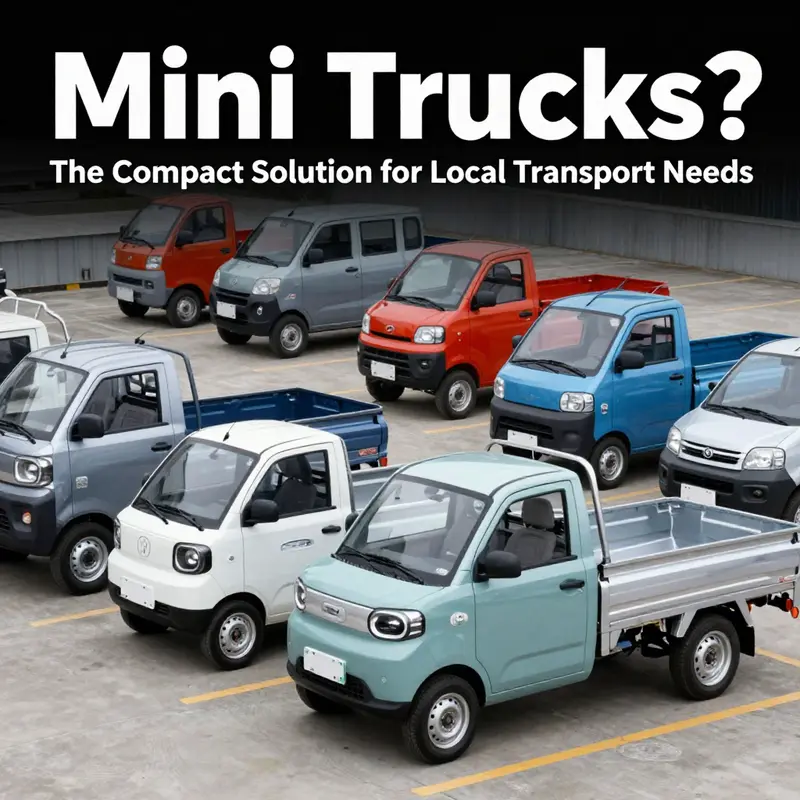

If you’ve ever found yourself needing a reliable, nimble vehicle for transporting goods or simply indulging in vehicular hobbies, the mini truck could be your perfect match. These compact vehicles are gaining popularity among local small business owners, residential property owners, and mini truck enthusiasts because they strike a balance between functionality and economy. In this piece, we will delve into what defines a mini truck, explore its innovative design features and various variants, and discuss the economic and environmental impact they bring to communities. Each chapter will provide insights into why mini trucks are not just vehicles but practical solutions tailored for the modern age.

Mini Trucks Demystified: Size, Specs, and the Everyday Utility of Micro Freight

A mini truck is not just a small vehicle with a cargo bed; it is a purpose-built response to a specific set of urban and rural logistics challenges. When we peel back the layers, what emerges is a compact, lightweight workhorse designed to bridge the gap between the agility of a scooter and the carrying capacity of a traditional pickup. The essence of a mini truck lies in its very core constraints: a total length of three and a half meters or less and a gross vehicle weight rating that sits at or below 1,800 kilograms. These limits, codified in certain regulatory systems, are not mere numbers; they shape every design decision, every load strategy, and every urban maneuver. In markets that codify these rules, the mini truck is the instrument of micro logistics, a vehicle tuned for short-distance cargo transport where the street grid, parking patterns, and fuel costs matter as much as payload and range. The practical outcome is a machine that can nap through congested lanes, squeeze into narrow alleys, and then deliver a modest payload without the fuss and expense of larger trucks. It is, in short, a tool forged for efficiency at the scale of a city block and the pace of a day’s work.

The silhouette of a mini truck is often boxy, echoing the van or the compact pickup but on a smaller frame. This boxy geometry is not merely stylistic; it is functional. A squared-off cargo area maximizes usable space within tight length restrictions and affords straightforward loading and unloading, a feature that becomes especially valuable in last-mile delivery, on construction sites with limited access, or in agricultural settings where either hand-loading or small mechanical aids are the norm. Inside, the cabin tends to be economical and utilitarian, prioritizing visibility, maneuverability, and reliability over luxury. The geometry of the cockpit is aligned with the vehicle’s mission: a low step-in height, a short wheelbase to sharpen turning latitude, and a bed or cargo area that can be tailored for boxes, crates, soil sacks, or tools depending on the day’s task.

Beyond the visual language, the mini truck is a practical exercise in scale. Its compact footprint makes it an obvious choice for dense urban centers where a full-size pickup would struggle to navigate with cargo aboard or to park without blocking bike lanes or pedestrian zones. In rural or peri-urban settings, the same compactness confers an nimble advantage when negotiating narrow lanes, farm lanes, or job sites where space is at a premium yet freight must move. The vehicle’s core appeal—mileage efficiency, tight turning radius, and ease of use—translates directly into lower operating costs. Even when payloads remain modest by the standards of larger trucks, the cost of ownership per delivered unit can be substantially lower, thanks to cheaper maintenance, lower fuel consumption, and reduced depreciation over time. This economical calculus has made mini trucks an attractive option for small businesses, co-ops, and individual operators who do not require heavy-haul capacity but do require dependable, predictable transport.

A central thread in understanding these machines is the way they are classified and regulated in different jurisdictions. In some systems, the mini truck is framed as a light-duty commercial vehicle with explicit constraints on length and weight. This is more than a bureaucratic footnote; it is a determinant of design language, available powertrains, and even the type of license or permit required to operate. The Chinese MIIT framework, for example, describes a micro-light truck in terms of size and mass thresholds, a formal recognition that helps standardize capabilities and expectations for fleets operating in and around dense urban cores. When a vehicle is designed to meet these limits, it can be optimized for the daily grind of city streets: efficient urban turning, predictable braking, and a powertrain that avoids excessive torque that would surge fuel consumption or impose insurance premiums out of proportion to its payload. In short, the regulatory envelope acts as a boundary condition that channels development toward a predictable, repeatable product category. This is not to say mini trucks are or should be uniform; within the same size and weight contours there is room for variation in suspension tuning, bed dimensions, and cabin layout, all of which reflect the diverse tasks that owners expect to complete.

The powertrain landscape for mini trucks spans two broad families: electric and internal combustion. Each brings distinct advantages and trade-offs, and the choice often hinges on where the vehicle will be used and what operation costs look like over time. Electric mini trucks are powered by compact electric motors, with rated outputs commonly in the small-kilowatt range. A typical urban-oriented electric model may feature 7.5 kW of continuous power, a setup that aligns with the low-speed, stop-and-go rhythms of city driving. The benefits are clear: zero tailpipe emissions, quieter operation, and significantly lower running costs when electricity is cheaper than diesel or gasoline and when maintenance demands are lighter than those of an ICE powertrain. The caveat lies in the battery. Battery longevity and performance degrade with temperature extremes and with aggressive charging and discharging cycles, so owners must weigh upfront price against ongoing charging costs and the practical need for range. Some electric mini trucks target ranges around 120 kilometers on a single charge, backed by packs in the vicinity of 12 kilowatt-hours. Such ranges are well suited to last-mile delivery routes, campus operations, or urban service fleets that return to a depot each day, where overnight charging can replenish the pack with minimal downtime.

Internal combustion engine mini trucks, by contrast, lean into traditional refueling convenience and potentially longer range. A gasoline or diesel setup can offer quicker top-ups and, in some cases, better payload-to-weight efficiency for longer routes where a full recharge would be impractical. The trade-offs here include higher fuel costs over the vehicle’s life, more complex maintenance regimes, and greater emissions. For operators who need to extend a day’s reach beyond a single urban line, a small ICE mini truck may prove more convenient than its electric counterpart, provided that fuel availability and maintenance supply chains are robust in the operating region. Regardless of propulsion, the design priorities converge on a few universal metrics: payload capacity, cargo bed usability, maneuverability, reliability, and total cost of ownership. The mini truck distills these priorities into a machine that is purpose-built for efficient, predictable transport over short to moderate distances.

The payload conversation, though, deserves careful framing. With a GVWR cap around 1,800 kilograms, the payload capacity of a mini truck typically sits in the mid-range of practical utility. In real-world terms, this usually translates to hundreds of kilograms of cargo, often enough for a week’s worth of deliveries for a small business, a stack of agricultural inputs to a field, or a full day’s supply run to a construction project or landscaping contract. The exact payload varies by model, chassis configuration, suspension tuning, and whether a vehicle is operating with a full fuel or battery load. Operators must also account for the weight of added equipment, such as a roof rack, a crane attachment on a worksite, or a refrigeration unit on a cold-chain job. Because the payload can be a moving target depending on the chosen configuration, many users choose a flexible approach: specify a target daily load, then pick a mini truck that offers a safe margin above that figure to preserve performance, handling, and braking within regulatory limits.

If we turn from the physics of the chassis to the everyday realities of operation, the advantages of mini trucks crystallize. In dense urban cores, their size translates into easier curbside parking, tighter loading zones, and more predictable travel times when congestion is high. In rural stretches, their light weight reduces the stress on road surfaces and keeps maintenance costs manageable, while still delivering enough cargo volume to justify a daily commute that would be impractical for larger trucks. For small businesses, the math often runs in two directions: faster lifecycle turnover of goods and lower capital outlay. A fleet of mini trucks costs less upfront than a small fleet of larger pickups, and each unit typically consumes less fuel, requires smaller tires, and benefits from simpler maintenance protocols. This combination translates into a smaller financial footprint and a shorter path to a positive return on investment, especially for enterprises that service a constrained delivery radius or a limited assortment of products.

The ergonomic and safety dimensions of mini trucks also deserve attention. A compact footprint does not automatically equal safer performance, but it does shape the expectations and design priorities. Shorter wheelbases can improve agility but may demand careful tuning of suspension and steering to prevent tailing or instability at higher speeds. Braking systems on mini trucks are typically sized to harmonize with the lighter mass, ensuring predictable stop distances on wet or uneven pavement. In urban scenarios, drivers often benefit from generous visibility due to high seating positions and large windows, a factor that enhances situational awareness when weaving through pedestrians, bicycles, and scooters. Safety packages—such as reinforced cabins, anti-lock braking, stability control, and modern driver-assistance features—play an essential role in elevating a mini truck from a simple tool to a durable partner on the road. Across markets, manufacturers and regulators tend to emphasize these elements to ensure that the vehicle remains responsible and resilient in the face of challenging operating environments.

A final, practical note concerns the ecosystem around mini trucks. Because size and function are so tightly linked, accessories, payload options, and service networks tend to be tailored to this class. For example, some operators adopt standardized crate sizes or pallet configurations that maximize cargo density within the bed while keeping the center of gravity low. Spares and quick-turnaround maintenance are important when a vehicle is the backbone of a small business; downtime translates directly into lost revenue, so service intervals are often planned around depot cycles or night-time maintenance windows. Even the process of charging or refueling a fleet of mini trucks is easier to choreograph than with larger vehicles. In the electric variant, depot-based charging minimizes downtime and yields better planning discipline for energy use. In the ICE variant, fuel scheduling and routine maintenance can be slotted into the day’s start-stop rhythm with minimal disruption to the core operations. These operational realities—how a mini truck is loaded, how it is fueled or charged, and how it is serviced—reaffirm the vehicle’s identity as a pragmatic tool for micro logistics rather than a demonstration of scale.

The broader takeaway is that a mini truck, by design, is a boundary-respecting instrument. It thrives within its limits by delivering reliable performance in the arenas where larger trucks struggle to justify the cost or feasibility. In urban lanes and rural backroads alike, it offers a balanced blend of maneuverability, efficiency, and practicality. It emerges as the natural answer for last-mile delivery, on-site service crews, and small-scale agricultural, landscaping, or construction tasks where the total landed cost matters as much as the total payload. The concept of a mini truck is not about padding a vehicle with extra features to chase a market trend; it is about disciplined, purposeful engineering that respects space, energy, and time—the resources that define modern logistics. The real story is not simply the size of the vehicle, but how that size interacts with constraints, costs, and the human needs it is designed to meet.

For readers curious about how different models approach these ideas, a concise resource focusing on model comparisons and specs can illuminate the practical differences between offerings in this segment. See the following internal link for a focused comparison and technical details: model comparisons and specs.

As these vehicles continue to evolve, the core characteristics that make mini trucks appealing will remain consistent: small footprints that unlock access, simple design that lowers maintenance, and a total cost of ownership that makes micro-scale logistics feasible for a wide range of operators. They are not substitutes for heavy-duty freight when capacity is the sole criterion; they are substitutes for the friction and cost associated with moving cargo in tight spaces, when every meter and every kilowatt saved becomes meaningful to the bottom line. The blend of size, weight, and powertrain options continues to shape a class of vehicles that is less about novelty and more about practical, repeatable performance in everyday service. In that sense, the mini truck is less a single model on a showroom floor and more a category of problem-solving mobility—shorelines of efficiency where the shorelines of congestion and distance meet.

External context helps frame how this niche fits into the broader world of light-duty transport. A general overview of what constitutes a light-duty truck, including regulatory and design considerations, provides useful perspective on why mini trucks occupy a unique space in modern fleets. For further reading on the broader landscape of light-duty trucks, see an external resource that surveys definitions, regulatory bases, and common use cases across regions: Light-duty trucks overview.

Micro Movers, Big Reach: Designing Mini Trucks for Urban Life and Wide-Scale Utility

Micro Movers, Big Reach: Designing Mini Trucks for Urban Life and Wide-Scale Utility

Compact by design yet capable by purpose, the mini truck sits at a crossroads of practicality and efficiency. It is not the smallest van or the lightest pickup; it is a purpose built tool for moving goods in places where space and maneuverability matter more than sheer volume. The defining idea behind a mini truck is straightforward: a compact vehicle that carries meaningful payloads over short to medium distances while weaving through city streets, tight loading bays, and crowded job sites with ease. In many markets, particularly where urban design favors dense development and limited parking, these vehicles answer a practical need that larger trucks cannot meet. Regulatory thresholds help frame what counts as a mini truck. In the Chinese context, for instance, the category is defined by a total length of 3.5 meters or less and a maximum gross vehicle weight rating, GVWR, of 1,800 kilograms or less. These figures translate to a vehicle size that stays nimble on congested roads while still offering a workable cargo box and a robust chassis. The exact numbers may vary by region, but the core principle remains fixed: maximize usable space and reliability within a footprint that never impedes access to the door of a shop, a back alley, or a narrow storefront.

Designing for urban life means thinking through a long list of constraints and opportunities. The most immediately noticeable feature of a mini truck is its compact size. The wheelbase is short, and the cargo box occupies the majority of the vehicle’s length, often resulting in a boxy, utilitarian silhouette that prioritizes interior geometry over elegant aerodynamics. The cargo area tends to be modest in overall volume, frequently described in practical terms as a few cubic meters that can be configured to fit a variety of goods, from tools and construction supplies to farm produce and small packages. The emphasis on a small footprint is not about diminutive capacity alone; it is about access. A shorter wheelbase and tighter turning radius enable the vehicle to squeeze into parking spaces that larger trucks would never approach. It is this combination of compactness and capability that makes the mini truck a staple for last mile delivery, municipal logistics, and the day-to-day tasks of small businesses.

The interior and cargo configurations reflect the same logic. Many mini trucks offer a flexible cargo bay with options for fixed walls, removable panels, sliding doors, and foldable seating. That flexibility is more than a convenience; it is a response to the diverse needs of users who must switch from transporting a pallet of bricks to a handful of hand tools, or from a soil-filled crate to a bundle of wooden planks. A well designed mini truck can adapt to a tradesperson’s toolkit, a vendor’s inventory, or a municipal crew’s equipment, often without requiring complex reconfigurations. In this sense, the vehicle is less a single-purpose machine and more a modular platform that can be tuned to the task at hand.

When we zoom out from the chassis and the cargo box, the powertrain becomes a key piece of the broader story. Mini trucks are offered in both internal combustion engine and electric variants, with the choice often driven by the economics of fuel, maintenance, and the local energy mix. Gasoline and diesel versions remain common where charging infrastructure is sparse or where upfront purchase costs need to be minimal. They typically rely on proven, durable powertrains that prioritize durability and ease of maintenance, traits that matter to small businesses managing unpredictable workloads. On the other hand, electric mini trucks are rising in prominence, especially in urban and peri-urban settings where zero emissions, quieter operation, and lower running costs deliver real advantages. An electric variant might pack a compact battery, delivering a practical range that covers a work shift or a series of daily routes with a comfortable margin for charging at the end of the day. While the exact range depends on battery size, vehicle weight, and climate, a compact 12 kilowatt-hour class pack can provide more than a hundred kilometers of range under typical urban conditions. This kind of capability translates into lower fuel costs, reduced maintenance complexity, and the potential for quieter operation in residential areas. Yet the economics of electric mini trucks are nuanced. Battery replacement cycles, charging infrastructure, and the higher upfront price can influence total cost of ownership, even as daily operating costs shrink over time. The balance among purchase price, energy costs, and maintenance is a crucial piece of decision making for fleets and individuals alike.

The payload capacity of mini trucks also reflects a careful balance between powertrain limits, chassis strength, and regulatory constraints. Modern designs commonly offer payload ranges from roughly six hundred kilograms up to about two thousand kilograms, depending on configuration and regional rules. This spread enables small businesses, landscapers, and municipal crews to select a vehicle that aligns with their typical load while keeping the vehicle within the acceptable weight envelope for urban roads and local bridges. A reinforced chassis and smart suspension choices help maintain ride quality and durability when the vehicle is loaded, yet still preserve handling characteristics that keep the truck responsive in tight spaces. The result is a work tool that behaves like a larger vehicle when loaded but remains as nimble as a compact utility vehicle when empty.

In daily use, the mini truck is often chosen for the combination of maneuverability and efficiency rather than sheer capacity. Its small cargo box may be less luxurious than that of a full sized pickup, but it is precisely the size that makes it practical for short hauls, everyday tasks, and frequent trips through urban centers. For small businesses, a mini truck can reduce the number of trips required to move a given quantity of goods, cutting fuel costs and lowering the risk of behind-schedule deliveries caused by traffic and parking delays. For municipalities, these vehicles support maintenance work, street cleaning, and equipment logistics in a way that keeps budgets in check while preserving service levels. Even for individuals with personal freight needs, the compact footprint can translate into easier storage, simpler parking, and more predictable access to urban infrastructure.

A note on the design language that underpins these vehicles helps connect the dots between form and function. The boxy cargo area, the upright driving cabin, and the flat floor are not cosmetic choices; they are deliberately chosen to maximize cargo flexibility, ease of loading, and driver visibility. The box shape also tends to simplify production and manufacturing, reducing stamping complexity and enabling modular interior layouts that can be adapted quickly to changing requirements. In markets where the weather and road conditions vary, choices around undercarriage protection, cargo area liners, and seat padding reflect a practical approach to durability and longevity. The goal is not to turn every mini truck into a luxury machine but to deliver a reliable, low maintenance vehicle that can withstand the daily grind while translating into predictable, repeatable results for the operator.

The story of variants broadens the scope beyond a single design template. Gasoline and diesel powered mini trucks remain a mainstay in many regions, prized for their accessibility and the breadth of service networks that support them. Electric mini trucks, however, are changing the calculus in places where charging infrastructure is available and where urban air quality and noise constraints matter. They offer lower operating costs and the prospect of near silent operation at low speeds, which suits early morning or late evening deliveries in dense neighborhoods. Beyond these two power sources, a third category worth noting is the utility task vehicle, or UTV based adaptations, which harness off road capability and ruggedness for farm, construction, or remote job sites. These adaptations expand the idea of a mini truck from a simple urban workhorse to a versatile platform that can handle challenging terrain while still being easy to move in and out of urban settings. In each case, the common thread is a focus on efficiency, reliability, and adaptability rather than sheer size or prestige.

To make sense of how these cars actually perform in the real world, it helps to think about the user journey. A typical operator will assess the route profile for a given day: the length of the trip, the anticipated traffic, the surface quality of roads, and the nature of the cargo. In cities with tight curb space, the ability to park near a loading dock, or to weave into a narrow lane, becomes a decisive factor in choosing a model. The opportunity to consolidate multiple small deliveries into a single voyage is a powerful driver of efficiency, and the mini truck is well suited to that role. The vehicle acts less like a single purpose conveyance and more like a mobile workspace that can be outfitted with tools, racks, or protective enclosures to suit a particular trade. A carpenter might carry long boards in a configuration that preserves load integrity, while a courier service would set up the cargo area with modular bins that allow quick, accurate unloading. The day might begin with a routine route and evolve into a dynamic set of on demand tasks, and in this landscape, the mini truck provides a flexible bedrock for execution.

The economics of owning and operating a mini truck hinge on a blend of upfront cost, maintenance simplicity, and energy consumption. A compact vehicle that uses fewer materials in its build—yet remains buoyed by robust axle design and a proven drivetrain—tends to be less costly to maintain than larger trucks. Energy costs vary with powertrain selection and local energy prices, but in aggregate they tend to favor vehicles that are lightweight and efficient. This dynamic matters most for operators who rely on a high cadence of trips, where the marginal cost of each additional mile matters a great deal. In addition, the smoother the ride and the more straightforward the loading process, the less time is wasted at each stop, which compounds to meaningful savings over a workday or a week. In practice, the choice between gasoline, diesel, and electric variants often comes down to the local business ecosystem: what is the price of fuel, how reliable is the electricity network, and how much downtime can be tolerated in exchange for lower emissions and maintenance needs. The mini truck, then, becomes a platform for optimizing those tradeoffs rather than simply a conveyance for moving goods.

In terms of market progression, the mini truck does not exist in a vacuum. It sits within a broader family of compact commercial vehicles that share a common goal: to democratize access to reliable, cost effective logistics in environments where traditional trucks are too large or too expensive to operate. The appeal is strongest where urban density, street geometry, and parking constraints converge with demand for last mile transport and on site utility work. This convergence explains why many fleets view mini trucks not as a middle ground between motorcycles and larger trucks, but as a distinct class of vehicle that unlocks practical capabilities previously out of reach. It is about enabling small businesses to scale operations responsibly, about giving municipalities a nimble tool for routine maintenance, and about empowering individuals to handle personal freight without needing a full sized truck in their driveway or garage.

For those navigating the selection process, a pragmatic approach begins with a clear articulation of needs. What is the typical load and the most common routes? How important is zero emission operation in the local area, and what are the practical limits of charging wherever the vehicle will be stationed overnight? What is the price tolerance, and how important are ongoing maintenance and spare parts availability? Answering these questions helps identify a configuration that balances payload, range, and cost. The next step is understanding how a mini truck fits within existing fleets or personal tool sets. For many users, the right choice is not a single vehicle but a series of configurations that share a common platform, allowing mixed use where some days demand more payload and others demand longer range or lower emissions. A modular approach to cargo and interior could include removable partitions, adjustable tie downs, and flexible seats that can flip and fold away when the space is required for larger items. In practice, this means operators can tune their vehicle for the task at hand while maintaining the ability to return to a standard, predictable layout for routine days.

If you are exploring how different mini trucks stack up in terms of design and capability, a concise, model neutral overview can be especially helpful. For a neutral comparison of mini truck models and their specifications and features, you can explore a dedicated resource that focuses on side by side evaluation rather than brand oriented marketing. This kind of comparison can illuminate how a compact footprint translates into usable cargo volume, how payload ratings are achieved without compromising handling, and how electric variants compare on range, charging time, and total cost of ownership. The idea is to provide a framework for understanding the tradeoffs that define this class, and to help readers translate the high level ideas of compact design into concrete decisions about what to buy or how to outfit a fleet.

In closing, the mini truck is not a gimmick or a passing trend. It is a durable, adaptable tool forged to meet the realities of modern urban life and the demands of small business logistics. It offers a practical compromise between space and mobility, delivering reliable performance in environments where bigger trucks would struggle with access, while still delivering enough load capacity to make daily work meaningful. Its evolution—through refinements in chassis, powertrain options, and interior configurations—reflects a broader shift toward efficiency and modularity in the commercial vehicle sector. For readers who want to dive deeper into the design principles and variants, a deeper dive into model comparisons and specs can be found through a dedicated resource that presents side by side evaluations of different mini truck configurations and their features. This kind of exploration helps translate the abstract idea of a compact work vehicle into real world guidance that can shape purchasing, fleet planning, and daily operations. For a broader industry context, explore the official mini trucks page from a major manufacturer to see how mass production translates the design ideas discussed here into practical availability on the market.

Small Workhorses, Big Footprint: Understanding What a Mini Truck Is and Its Economic and Environmental Role

A mini truck, at its core, is a compact, purpose-built workhorse designed to move light cargo over short distances with agility and efficiency. Its defining features are pragmatic rather than flashy: a total length of three and a half meters or less, and a maximum gross vehicle weight rating of about 1,800 kilograms or less. These thresholds, grounded in regulatory frameworks such as those used by the China Ministry of Industry and Information Technology, create a category of light-duty vehicles that occupy the space between a traditional small van and a larger pickup. The consequence is a vehicle that can navigate tight streets, squeeze into narrow parking spaces, and perform daily payload duties that would be impractical for bulkier machines. In practical terms, a mini truck is designed to be a reliable, economical carrier for small-scale logistics, neighborhood deliveries, and personal freight tasks that demand both maneuverability and cargo capacity.

The form of a mini truck typically balances the compact silhouette of a van with the bed or flat cargo area of a pickup. This combination yields a boxy, utilitarian profile that maximizes usable space without sacrificing the ease of handling in congested environments. The vehicle is intentionally lightweight, which translates into nimble handling and lower energy use in urban settings. The design prioritizes a straightforward, rugged utility: generous cargo access, a bed that can tolerate daily loading and unloading, and a chassis that remains responsive at city speeds. Though the exact appearance varies by market and manufacturer, the underlying logic remains consistent—achieve maximum practical payload within tight dimensions, while keeping costs predictable for owners and operators.

Powertrains for mini trucks span the spectrum from traditional internal combustion engines to modern electric propulsion systems. Internal combustion variants continue to offer familiar driving characteristics and wide fueling infrastructure, which keeps them relevant in markets where charging networks are still developing. On the other side of the spectrum, electric mini trucks bring a distinct advantage to urban logistics. A compact electric model may pack around a dozen kilowatt-hours of battery energy, yielding city-focused ranges that comfortably cover routine delivery routes. In practical terms, a small electric mini truck can perform daily last-mile tasks with minimal refueling downtime, reducing idle costs and providing a quiet, low-emission alternative to diesel or gasoline equivalents. The environmental premium of electric power scales with usage patterns; as fleets adopt more of these vehicles, the cumulative benefits for city air quality and neighborhood livability become increasingly evident.

The operating logic of mini trucks aligns with the needs of crowded urbanism and dispersed rural supply chains alike. They excel in last-mile delivery, where cargo volume-per-trip must be balanced against the ability to locate, unload, and return quickly. They suit small businesses that require on-site deliveries to customers, storefronts, or work sites where parking is scarce and access is constrained. They also appeal to individuals who need to transport tools, equipment, or materials without the commitment and expense of a full-sized truck. The result is a versatile tool in the modern logistics toolkit—one that can be deployed across diverse contexts with predictable economics and a reduced environmental footprint relative to larger heavy-duty trucks.

From a regulatory and planning perspective, mini trucks fit neatly into urban and regional strategies aimed at mass mobility, congestion relief, and more efficient land use. Their compactness translates to lower demands on parking infrastructure and road space, smaller impact on street wear, and the potential for a more dynamic mix of mobility and freight activities within dense urban cores. The regulatory landscape often reflects these practical benefits, offering streamlined registration, favorable tax treatment, or incentives for low-emission variants. For fleets contemplating a transition away from larger delivery vehicles, mini trucks present a pathway to maintain service levels while reining in capital expenditure, operating costs, and urban impact.

Economic life in this segment is driven by several interlocking forces. First, the purchase price for a mini truck is typically lower than that of a mid-size or heavy-duty pickup. This lower upfront cost matters not only to individual buyers but to small businesses and delivery operations with tight capital budgets. Second, operating costs tend to be leaner. With smaller engines or efficient electric drive systems, daily running costs—fuel or electricity, maintenance, and tires—are kept to a minimum. The lighter weight and simpler drivetrain architectures can translate into fewer parts that wear, which in turn reduces the long-term maintenance bill. Third, many regions offer incentives for fuel-efficient or zero-emission vehicles, and mini trucks, particularly the electric variants, can qualify for subsidies, tax breaks, or favorable depreciation regimes. These incentives can markedly improve the total cost of ownership over the vehicle’s life, tipping the balance in favor of small-scale fleets that must maximize every dollar in a tight margins game.

For small businesses, the economic case often rests on a straightforward equation: the cost of ownership divided by the number of useful trips per year should yield a favorable cost-per-delivery. When a fleet relies on multiple small vehicles instead of a handful of larger trucks, logistical flexibility increases. The reduced footprint of each vehicle translates into easier parking and shorter route planning cycles, allowing more deliveries per hour and less idle time at curbside. In neighborhoods where street restrictions or loading zones limit the presence of bulky trucks, mini trucks can maintain steady service without triggering the same level of infrastructure strain. This efficiency can compound through the supply chain, helping small operators scale their operations without taking on the risk and expense associated with larger assets. The municipal implications are also notable. A fleet composed of compact vehicles can reduce urban parking demand, ease street congestion, and contribute to a more efficient use of curb space, which is often a scarce municipal resource. The economic benefits at the city level emerge as a blend of direct savings for operators and broader productivity gains that ripple through local economies.

From an environmental viewpoint, mini trucks contribute to a growing consensus that the urban freight problem can be addressed not only with more roads or bigger trucks, but with smarter, smaller vehicles that are aligned with city life. The environmental case strengthens when electric propulsion is employed. Battery electric mini trucks offer the promise of lower tailpipe emissions, reduced noise, and a cleaner urban air environment. Their smaller scale also means less embodied energy in manufacturing and lighter loads during operation, factors that cumulatively reduce resource demand across a vehicle’s life cycle. The emissions profile improves further when electricity is generated from clean or low-carbon sources, creating a layered benefit: less pollution at the point of use and a smaller carbon footprint over time as the grid decarbonizes. Studies that model emissions across vehicle categories consistently highlight that smaller, well-optimized electric vehicles can be among the most effective tools for decarbonizing city logistics, particularly when fleets shift toward electrified micro-mupply chains rather than relying on multiple larger diesel trucks.

In this broader frame, mini trucks act as a practical bridge between mobility and freight, enabling a more versatile and sustainable approach to everyday logistics. They are not a universal solution to all transportation problems, but they offer a compelling combination of economic accessibility and environmental prudence for certain use cases. They support a shift toward more localized fulfillment, closer to customers, and smaller, more frequent deliveries that short-circuit the energy-intensive cycles often associated with longer-haul freight. The cumulative effect is a fleet that can grow with a business without proportionally escalating costs or environmental impact. As cities reimagine streets and deliveries to improve air quality, noise levels, and pedestrian safety, the role of compact, efficient freight vehicles becomes more pronounced. These are the traits that tie a simple definition—what is a mini truck?—to a wider story about how goods travel through urban and rural landscapes in the twenty-first century.

The literature on emissions and energy use provides a rigorous backdrop to these observations. In particular, analyses of micro-sized battery electric vehicles indicate that smaller electric fleets can deliver the lowest CO2 emissions among competing vehicle categories under a range of future scenarios. This is not a claim about a single model or a specific market; it is a reflection of the intrinsic efficiency advantages of compact footprints, improved aerodynamics for their class, and the favorable energy dynamics when electricity dominates the powertrain. The argument gains additional weight when considering the material and energy intensity of manufacturing: the smaller the vehicle, the less material is required, and the more discreet the energy draw over the vehicle’s life cycle. While the precise outcomes depend on local energy mixes and vehicle usage patterns, the directional message remains clear—mini trucks, especially electric variants, offer meaningful environmental benefits when deployed thoughtfully within urban freight ecosystems.

For readers who wish to delve deeper into the environmental and economic dimensions of mini-sized electric vehicles, the referenced study provides a foundational perspective on emissions trajectories and future demand dynamics. This work situates the discussion within a broader climate and energy context, helping to connect micro-scale vehicle decisions with macro-level sustainability goals. As fleets, cities, and businesses experiment with different configurations, the insights from this body of research help illuminate how a small, efficient vehicle can contribute to a larger plan for cleaner air, more efficient urban logistics, and a resilient, low-carbon economy.

In practice, the adoption of mini trucks sits at the intersection of technology, policy, and everyday operational realism. Fleets contemplating a transition weigh the upfront costs against the long-term savings from lower maintenance and fuel or electricity, while also considering the regulatory incentives that can alter the economic calculus. They examine cargo needs—whether a few hundred kilograms or roughly a ton per shift—and how the vehicle’s payload aligns with route geometry, parking availability, and loading dock permissions. They map charging or fueling options into the daily rhythm of deliveries, ensuring that the vehicle can return to base with ample reserve to carry out the next cycle. They assess the infrastructure landscape: the availability of charging stations, the reliability of electrical grids, and the potential for on-site charging at depots or customer locations. In short, the decision to deploy mini trucks is not merely a purchase choice; it is a strategic adjustment to a logistics system aimed at improving cost efficiency, speed, resilience, and environmental performance.

As the discourse around urban freight evolves, mini trucks emerge as a practical instrument of change. They embody a philosophy that values nimbleness, cost discipline, and ecological responsibility in equal measure. They are not a cure-all, but they are a meaningful instrument in the toolkit of solutions designed to untangle the frictions of city delivery, support small business growth, and contribute to healthier, more livable urban environments. The continued refinement of their technology, combined with supportive policy frameworks and thoughtful urban planning, will determine how quickly and how deeply these compact vehicles reshape the landscape of modern logistics. And within this evolving narrative, the essential question remains both simple and profound: what is a mini truck, and why does it matter as a cartridge of economic and environmental improvement in everyday transportation and commerce?

For readers seeking a concise gateway to related reflections on micro-mobility and fleet composition, the Minitrucks Scala blog offers accessible discussions and case studies that explore how these vehicles fit into broader fleet strategies and urban delivery experiments. Minitrucks Scala blog.

External resource for further reading: Mini-Sized Battery Electric Vehicles: Emissions and Future Demand. https://www.sciencedirect.com/science/article/pii/S0301421616302879

Final thoughts

In conclusion, mini trucks epitomize the ideal combination of practicality, efficiency, and adaptability for today’s transportation needs. With a firm understanding of their definition, design features, and economic and environmental contributions, local small business owners, property managers, and enthusiasts can appreciate how mini trucks serve as invaluable assets in urban landscapes. Whether you are contemplating their purchase or simply exploring options, the versatility and benefits of mini trucks remain irreplaceable.